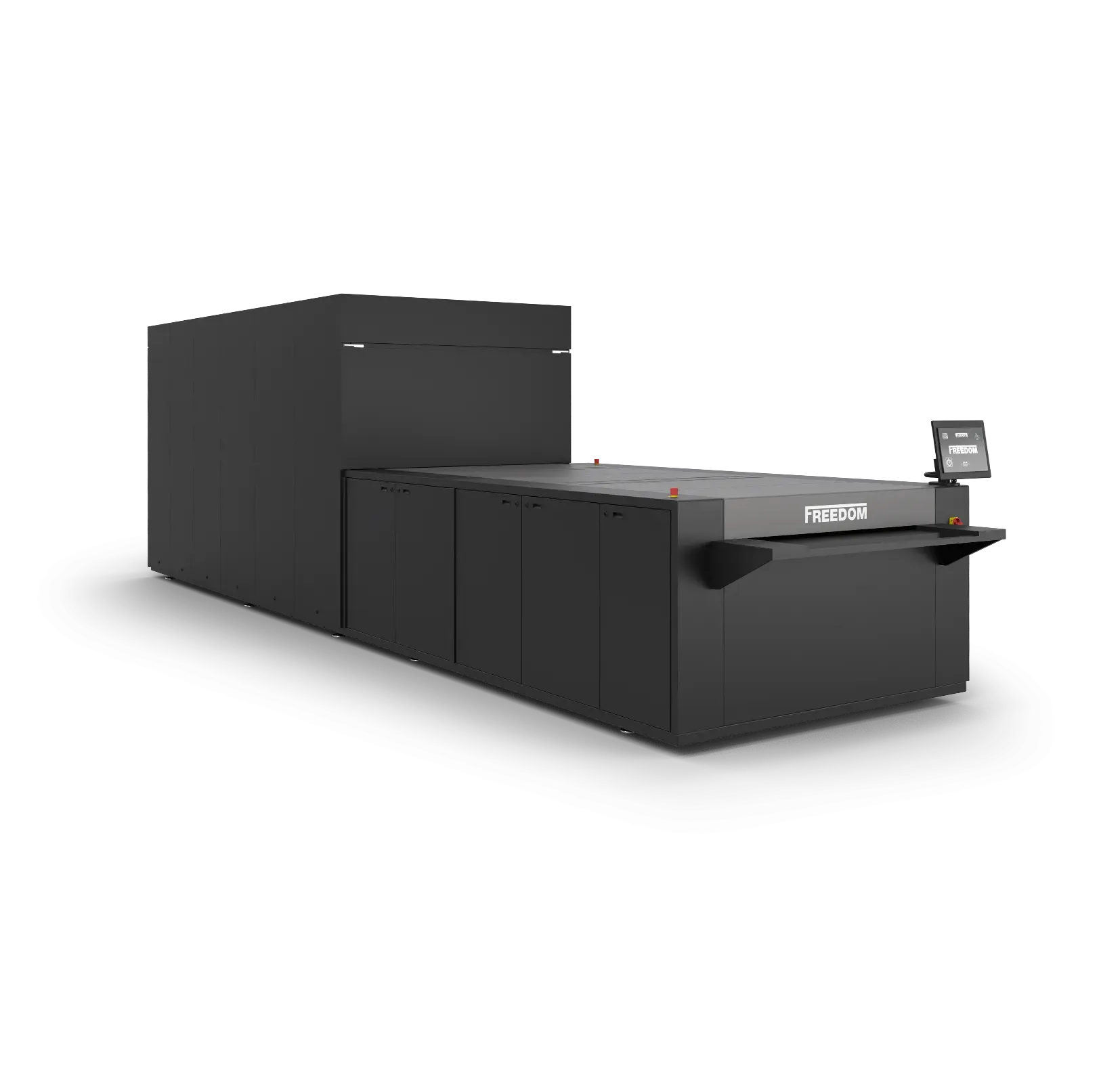

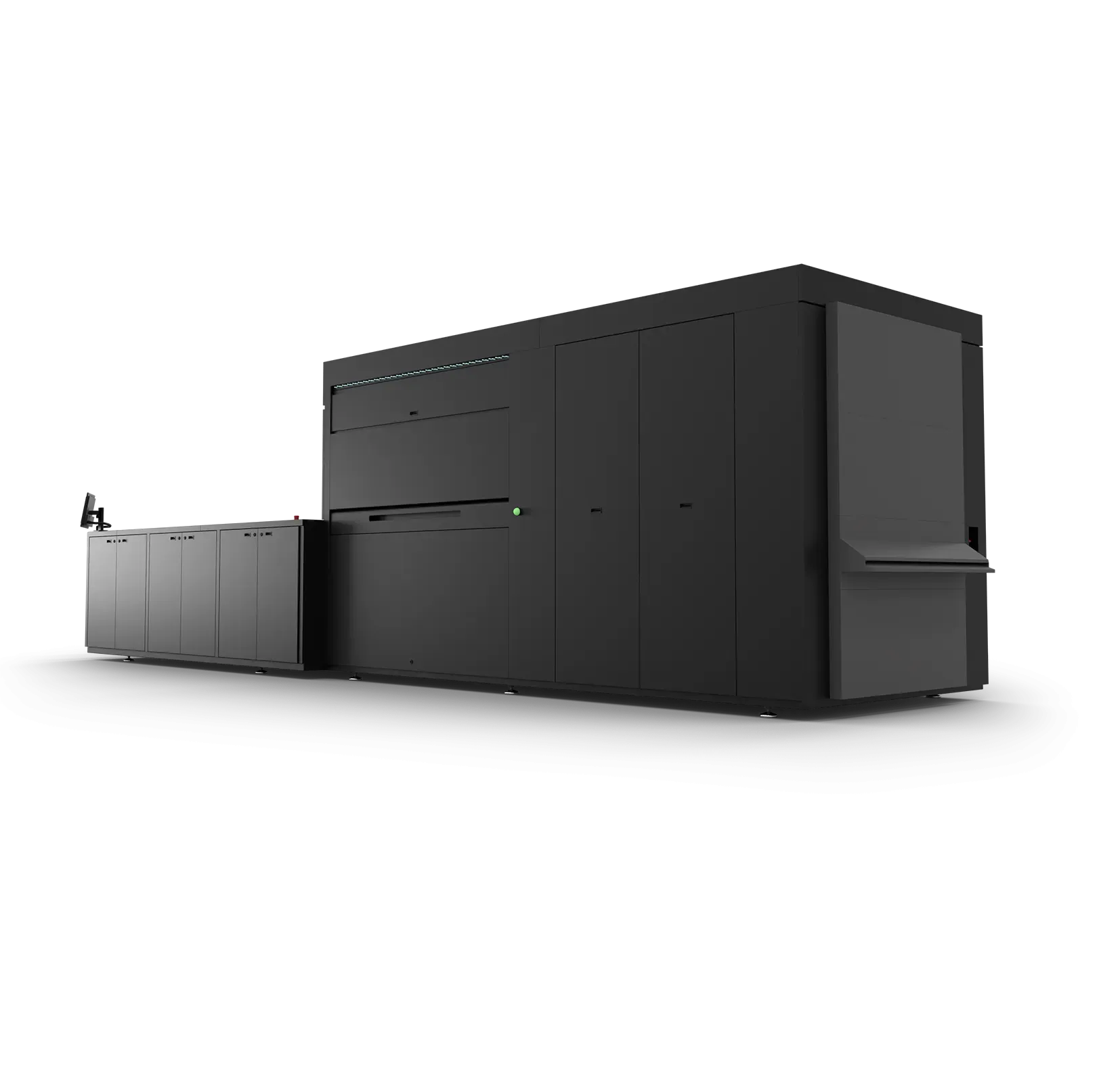

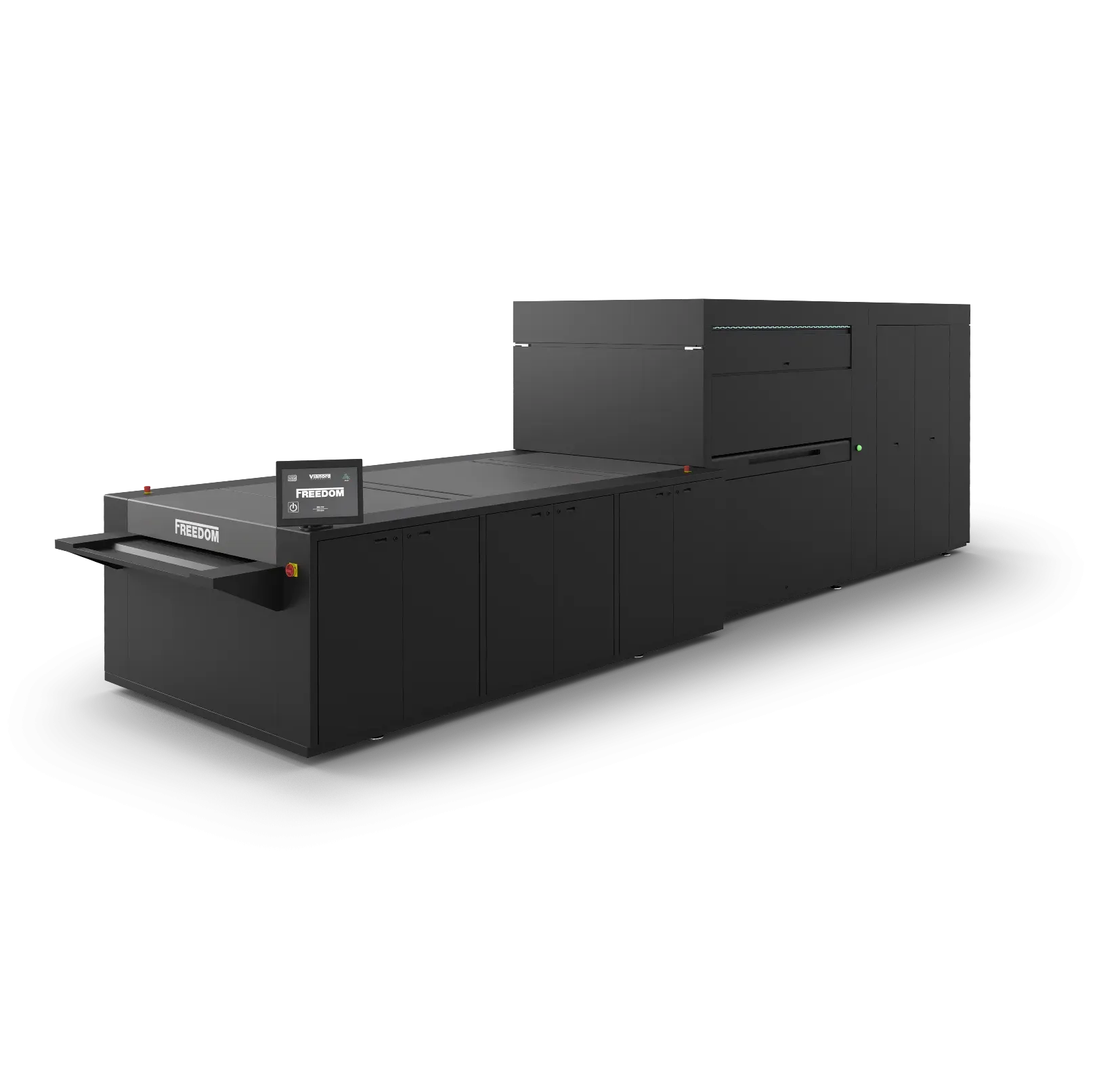

The FREEDOM automatic system by Vianord Engineering combines a compact footprint with a fully automated workflow for flexographic plate processing. As the most compact automated solution on the market, it enables complete automation—including seamless integration with imaging and LED exposure—without the need for a bridge. FREEDOM units offer rear or side plate exit options, with side access for live plate inspection and the flexibility to dry and finish plates processed by other washout units.Thoughtfully designed for both productivity and practicality, the system provides easy access for servicing and maintenance. Featuring an intuitive new interface and integrated Dryer+ technology, FREEDOM delivers high-end performance tailored to flexible, space-conscious production environments.

The market’s most compact inliner

Maximum efficiency

Minimal footprint

General Features

- Market's Smallest Inliner: Ultra-compact design. 842 x 220 x h215 cm

- Integrated Dryer+ Technology for enhanced drying performance

- New User Interface & Touch Screen: comfortable, intuitive, bigger, includes an external terminal for unit remote control

- Remote access

- Plate process parameters memory (up to 30 channels)

- Programmable warm up/switch off

- Active component visualisation during the process

- Manual function to run the components separately (Service only)

- Plate Tracking & Manual Change Detection: auto-updates when changes are made

- Integrated Data Export Enables quick export of production data for easy tracking, and optimisation

Encumbrance

The minimum distance should be of 1.5 mt (59”) in front, on the right side and at the left side 1 mt (40”).

The respect of the minimum distance from the walls is critical to allow sufficient space to the users and the engineers to be able to have access to the system in case of maintenance and repairs.

Smart Entry Section

- Versatile Plate Feeding Supports both manual and automatic feeding without requiring any extra piece of equipment.

- Automatic Plate Handling: The system automatically aligns, punches, loads, and clamps the plate to the pin bar

- Smart Pin Bars Automatic Recovery: Automatically punches, loads, and clamps the plate to the pin bar. After processing, the used pin bar is sent to storage (up to 4 pin bars capacity). When a new plate is ready, a pin bar is automatically retrieved and positioned for the next cycle.

Washout Section

- Separate pre-wash to prevent solvent contamination with LAMS layer

- 2 pre-wash & 22 washout brushes, dedicated cleaning, wiping, and back cleaning brushes

- Oscillating and rotating movements

- 3D Brush Motion, smooth start and reduced vibrations

- Automatic brush oscillation realignment

- precise solid content analysis

- Automatic solvent replenishment with programmable fresh solvent control

- Adjustable Fresh solvent flow regulation

- Constant preset solvent temperature

- Upgraded cleaning and wiping system

- Quiet operation

- Optimized bristle action with automatic speed synchronization

- Integrated exhaust system

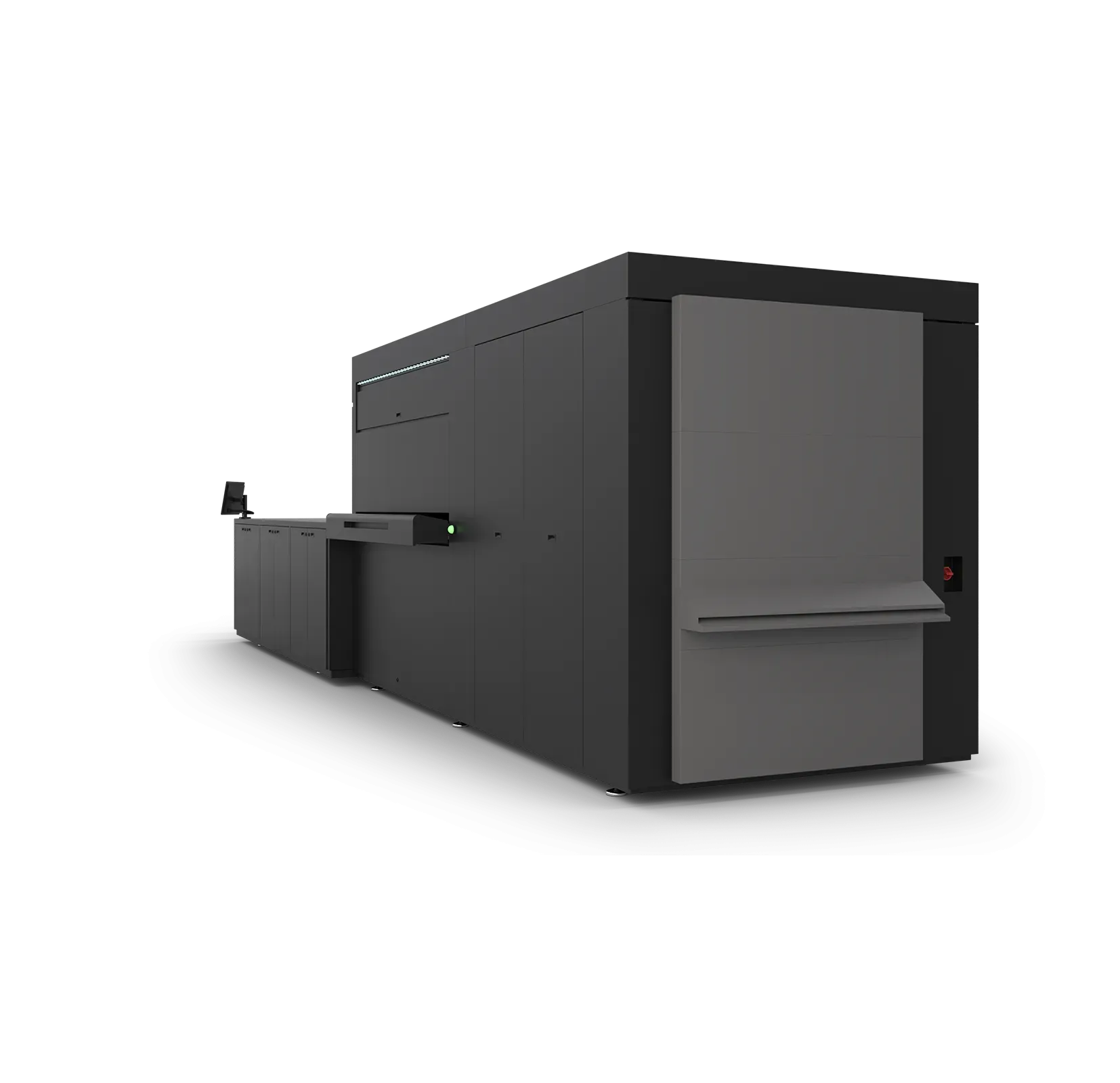

Lateral Plate Exit

- Extra height +30cm

- Makes the system adaptable to footprint requirement

- Multi-Step Inspection Enables plate inspection at each stage to ensure quality and detect issues early.

- Flexible Integration Lateral manual feeding ensures workflow efficiency and seamless integration with existing washout systems.

Dryer+ Section

- New, ultra-fast, patented drying technology

- Intelligent system for auto-positioning the nearest drawer

- 8 drawers with independent control

- High productivity with optimised drying efficiency

- Overall lower temperature

- 50% faster preheating

- Balanced heat and cold air for optimal evaporation

- Safety thermostat in every section

- Integrated exhaust system

- Exhaust control with built-in safety mechanism

- Dedicated Plate Cooling Area to ensure consistent results with optimised cooling

Light Finisher-Stacker Section

- 1 drawer for UVA + UVC lamps for post exposure and light finishing

- Programmable operation: simultaneous/separate/sequential

- Independent timers for UVA and UVC

- Air flow cooling system

- Automatic plate cooling with programmable time

- Fiber optics for lamp failure detection

- integrated exhaust system

- 7 drawers for stacking finished plates (8 with lateral plate exit)

At just 8.42 meters long and 2.2 meters wide, this ultra-compact system redefines streamlined productivity. Featuring smart plate automation, revolutionary low-temperature drying, multi-step inspection, intelligent control, and reduced energy consumption.

Designed for full integration, secure access, and consistent performance.