Washout units for the preparation of water washable flexographic printing plates, often use rotary brushes to remove from the surface of the plate the unhardened polymeric material (i.e., the monomer).

During the plate preparation the polymer is hardened by exposing the part interested with ultraviolet radiations. The unexposed part is then removed during washout, leaving all the exposed part in relief. The raised part is used to transfer printing ink to the substrate (paper, plastic, etc.).

The washout of the flexographic plates takes place thanks to the mechanical effect (abrasion) caused by the bristles of the brushes when they get in contact with the surface of the photopolymer plate.

The above-mentioned abrasion effect is facilitated by the presence of a waterbased solution, where the necessary treatment fluid depends on the type of flexo plate used.

The washing-out brushes are normally composed of a single spiral of filaments which are locked onto a cylindrical support.

The brushes themselves wouldn’t deteriorate quickly, and their potential duration could be rather long. However, despite the lubrication effect provided by the water-based solution, the monomer tends to settle between the spirals of the brushes which hardens and make them become ineffective.

After a certain period, the brushes are therefore contaminated and, to maintain sufficient washout quality, it becomes essential to regenerate them.

Up until recently, the only way to regenerate such Brushes was by replacing the Brushes themselves or in some cases replace the Bristles Spiral; making it very expensive for the user.

Vianord developed a system for removing the monomer from the spirals, which substantially reduces the maintenance costs of the developer and increases the average life of the wash-out brushes exponentially.

The Rotary Brush Regeneration unit was designed to scrub the processors brushes on at a time.

CE Certification

The equipment is designed and manufactured according to the EEC safety and health standards and on the basis of the verifications carried out according to the essential requirements of the Directive 2006/42/EC, the system respects and is in compliance with all the applicable points.

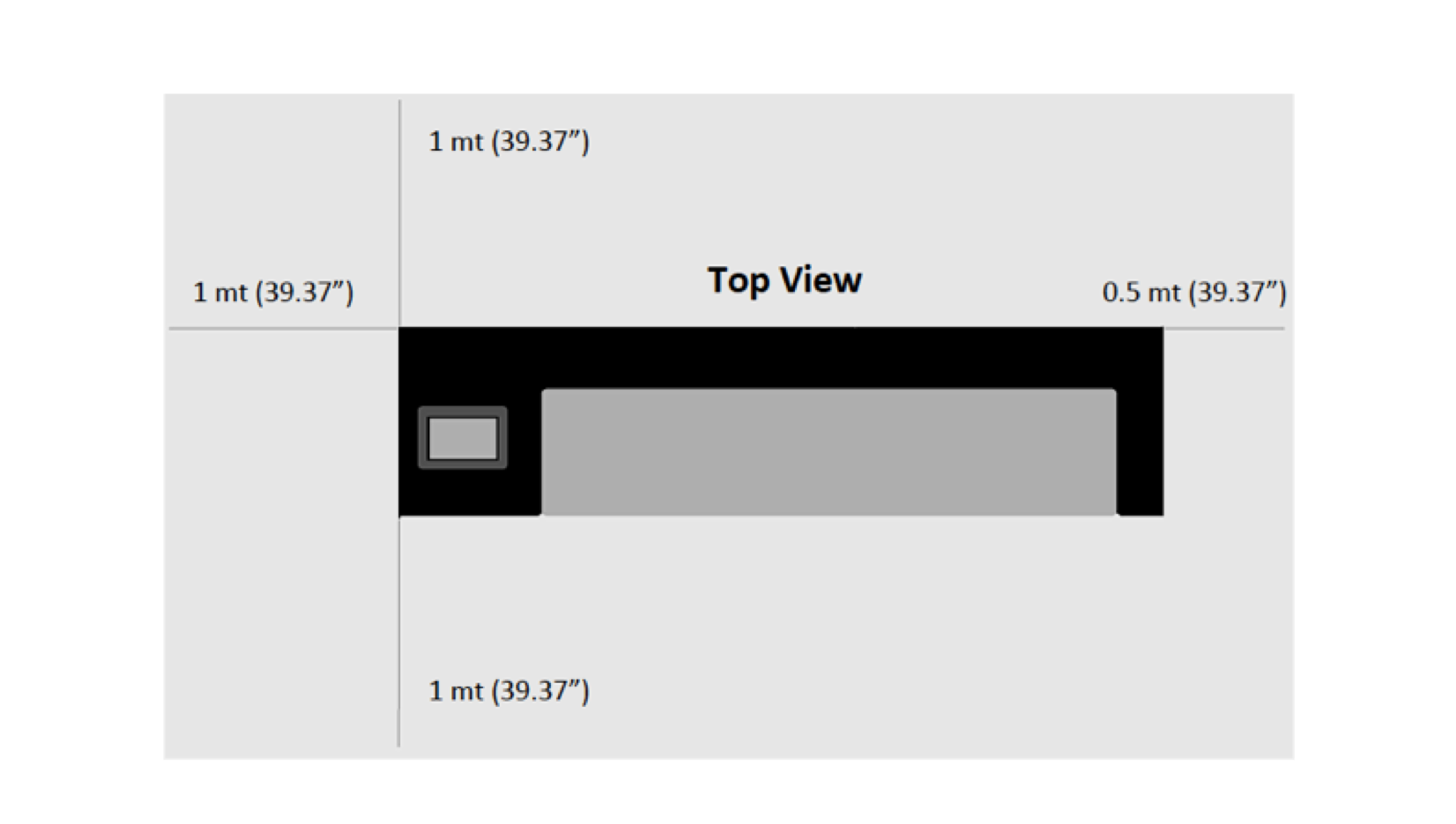

System Dimensions (net)

Dimensions (L x W x H): 145 x 52 x 106 cm - W w/Brush Holder 60 cm - H w/Lid open 149 cm; 57.08 x 20.47 x 41.73 Inch - W w/Brush Holder 23.62 Inch - H w/Lid open 58.66 Inch

System Weight (net)

150 Kg (330 lb)

Mains Electricity

Brush Cleaner

Power Supply

230 Volt – 50 / 60 Hz - 1Ph / N / PE

Current (nominal load)

1.5 A

Power Rating (nominal)

0.3 Kw

Suck Up Unit

Power Supply

230 Volt – 50 / 60 Hz - 1Ph / N / PE

Current (nominal load)

4.5 A

Power Rating (nominal)

0.8 Kw

Grounding

Working Environment

The system should be installed in a clean, constant-temperature and constant-humidity pre-printing environment with a temperature between 18 and 26°C (64.4 and 78.8°F) and a non-condensing relative humidity in the range of 40 to 60%.

To maintain such environmental standards an efficient heating/cooling and ventilating system may be required.

System Colour

Vianord offers all equipment in standard powder coating Vianord Black.

In addition, Vianord offers numerous ways you can personalize your system. In fact, Vianord offers the best customization options in the industry! This allows you to showcase your brand and company’s spirit in ways other companies can’t offer. You can choose your personal colour and have your logo, company name, or slogan pop.